Vacuum evaporator for process water treatment

DREFI has attended to the problems of process water treatment and offers a system which has many advantages compared to the conventional methods of process water treatment. The FIDI-system is able to solve problems in a technical, economic and ecological way. The principle is based on evaporation of waste water under negative pressure (residual pressure approx. 30 mbar). The boiling temperature of the waste water is 30°C.

The low boiling temperature combined with the construction of the industrial plant offers many advantages such as:

- No thermic decomposition of the product in the waste water (further use)

- Very little encrusting

- Very good distilling results (further use)

- High concentration of residue

- Low use of energy

- Fully automatic SPS-controlled method of operation requires low employment of staff

- With one industrial plant different kinds of waste waters can be chemically treated

FIDI-vacuum evaporators are built in a standard make with a daily output of 150-20.000 ltrs. (bigger on demand). The units are totally independent and can be used 24 hours a day. The range of application is almost unlimited.

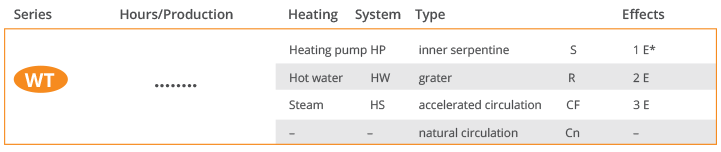

The industrial plants are manufactured in different series of models, so your specific requests can be considered.

Our innovative construction of the units makes it possible to develop and construct an optimal system for you!

FIDI Evaporators

Solving the problem of disposing industrial wastewaters: Lowering residue volumes as well as recycling wastewater or simplifying wastewater disposal.

FIDI EVAPORATORS operate the way that water is separated from other products, which are dissolved herein. The (liquid) solution is boiling during the evaporation process. The water steams away, condensates and the condenser water is draining. Those contaminations, which are less exhalable, remain in the evaporator and are discharged afterwards.

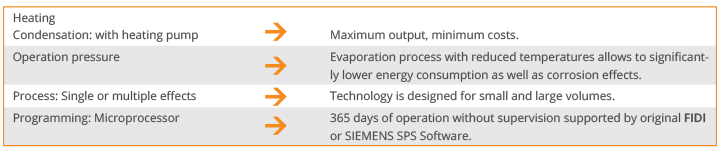

Advanced and modern technology

Identification

Application fields

FOOD AND CONFECTIONERY INDUSTRY:

- Recovery and concentration of sugar solutions

GRAPHIC ARTS AND PHOTOGRAPHIC LABS:

- Concentration of developing and fixing baths

- Concentration of roller rinsing water

- Recovery of inks from the washing water

DUMP SITES:

- Treatment of percolation water

OENOLOGY:

- Concentration of must

- Elimination of sulphate

- Preparation of medical herbs

- Recovery of solvents utilised for extraction process

MEDICAL PLANTS:

- Recycling of solvents being used during extraction

PHARMACEUTICAL, CHEMICAL, COSMETIC INDUSTRY:

- Wastewater retreatment coming from reactor operations

and washing

GALVANIC INDUSTRY:

- Recovery of metals from washing process

(Chromium, Nickel, Copper) - Concentration of polluted baths

(degreasing, pickling) - Recovery of solvents utilised for extraction process

RUBBER INDUSTRY:

- Recovery of vulcanisation salts

- Purification of washing water

DAIRY INDUSTRY:

- Recovery of proteins from milk wheye

MECHANICAL INDUSTRY:

- Concentration of oily emulsions

- Concentration of liquids from finishing processes

- Concentration of washing baths

OIL MILLS:

- Treatment of water from oil presses

GOLDSMITH´S INDUSTRY:

- Concentration of washing and picking process

- Recovery of gold from the residue of the treatment process

PRESSURE DIE-CASTING:

- Concentration of working liquids

(detaching product, glycol, lubricants)

FOOD INDUSTRY:

- Recovery of food additives from different industrial

process liquids

COLD MEATS AND SALAMI INDUSTRY:

- Concentration of process broth

- Recovery of greases and gelatine

DRY CLEANER‘S PLANT:

- Recovery and concentration dyes and washing liquids

THERMAL TREATMENT:

- Recovery of tempering salts

- Purification of washing water

PAINTING PLANT:

- Concentration of oily emulsions

- Recovery of solvents

- Concentration of phosphoric degreasing baths