LMW 115 Kombi AM/M

Trend-setting cabinet washers for solvent and aqueous cleaner.

2 ergonomic constructed washers in one unit.

- Completely robust stainless steel units. Both the washing room which is for the automatic wash cycle (solvent part) and the unit is completely made of stainless steel

- Washing of up to 4 spraying guns at the same time possible

- Use of approved, robust, booster pumps

- Shop air with pressure reducer for blow out or spraying gun

- Automatic and manual cleaning at the same time (solvent part) and manual cleaning (aqueous part) possible

- Little cleaning and solvent wastage

- Powerful suction

- Installation in zone 1 qualified. CE compliant according to Atex 2014/34/EU

Solvent-Washing Unit

- Automatic, timer controlled washing room. 2 gravity feed spray guns can be washed at the same time as standard

- Automatic washing room with 15 cleaning blast pipes

- Automatic and manual cleaning at the same time

- Broad manual washing room

- Brush start-up with adjustable output in the circulation process

- Connectable fresh solvent jet for rinsing

- Adjustable brush output achieved by running a pump

- Automatic suction of solvent vapours

- Collecting tank (stainless steel) for bin

Aqueous-Washing Unit

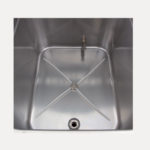

- Broad manual washing room

- Continuous-flow brush start-up with circulation cleaner for manual cleaning

- Continuous-flow brush start-up with public water flow for rinsing

- Broad manual washing room

- Connectable fresh solvent jets for rinsing

- Coagulation function in basin with connectable support of coagulation process

- Coagulation set four-part

measurements: (L x W x H) 1090 x 670 x 1465 mm

weight: 109 kg

shop air: 6 – 10 bar

diameter suction: 150 mm